In the world of printing, two popular techniques stand out: DTF Transfer printing and traditional screen printing. Each method has its unique features, advantages, and challenges. Understanding these differences can help you choose the right printing method for your needs, whether you're designing custom apparel or creating promotional materials. This article will break down the key aspects of both techniques, making it easier for you to grasp their similarities and differences.

Key Takeaways

- DTF Transfer printing uses a special film to create vibrant designs that can be easily applied to various fabrics.

- Traditional screen printing requires separate screens for each color, making it less flexible for complex designs.

- DTF is often more cost-effective for small batch orders compared to screen printing, which is better for large quantities.

- Both methods can produce durable prints, but DTF prints are known for their softer feel on fabric.

- Choosing between DTF and screen printing depends on your specific project needs, such as design complexity and order size.

Understanding the Basics of DTF Transfer Printing

What is DTF Transfer Printing?

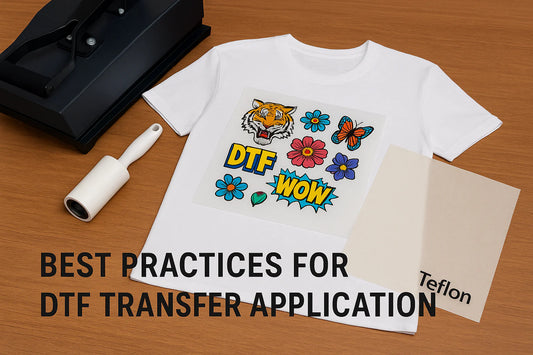

DTF Transfer printing, or Direct-to-Film printing, is a modern method for creating custom designs on various materials. This technique allows for vibrant, full-color prints that can be applied to fabrics using heat transfers. Unlike traditional methods, DTF printing excels in producing intricate designs with high detail.

How Does DTF Transfer Printing Work?

The DTF process involves several key steps:

-

Design Creation: A design is made on a special film.

-

Printing: The design is printed using a DTF printer, which uses water-based inks.

-

Adhesive Application: An adhesive powder is applied to the printed film.

-

Heat Transfer: The film is placed on the fabric and heat is applied using a heat press, transferring the design onto the material.

Materials and Tools Needed for DTF Transfer Printing

To get started with DTF printing, you will need:

-

DTF Printer: For printing designs onto film.

-

DTF Film: A special film that holds the printed design.

-

Water-Based Inks: Used in the printer for vibrant colors.

-

Adhesive Powder: Helps the design stick to the fabric.

-

Heat Press Machine: Essential for transferring the design onto the fabric.

DTF Transfer printing is a game-changer for custom apparel, allowing for creativity and personalization without the high costs of traditional methods. Explore the possibilities with DTF!

Traditional Screen Printing: An Overview

What is Traditional Screen Printing?

Screen printing is a classic method used to create designs on various materials, especially fabrics. It involves using a mesh stencil to apply ink onto the surface. This technique has been around for many years and is known for its durability and vibrant colors.

The Screen Printing Process Explained

The screen printing process can be broken down into several steps:

-

Design Creation: The first step is to create the design you want to print.

-

Screen Preparation: A mesh screen is stretched over a frame. This screen will act as a stencil for the design.

-

Emulsion Coating: The screen is coated with a light-sensitive emulsion that hardens when exposed to light.

-

Exposure: The screen is exposed to light, which hardens the emulsion in areas not covered by the design, creating a stencil.

-

Ink Application: Ink is pushed through the screen onto the fabric, transferring the design.

-

Drying: The printed fabric is then dried to set the ink.

Common Uses of Screen Printing

Screen printing is widely used for:

-

T-shirts: Custom designs for events, businesses, or personal use.

-

Banners: Large prints for advertising or events.

-

Promotional Items: Items like tote bags, hats, and more.

Screen printing is a reliable method that produces high-quality prints, making it a popular choice for bulk orders. Its ability to create vibrant colors and detailed designs makes it a favorite among businesses and individuals alike.

Comparing DTF Transfer Printing and Traditional Screen Printing

Differences in Printing Techniques

DTF Transfer Printing and Traditional Screen Printing are two popular methods for creating custom designs on fabrics. Here’s how they differ:

-

DTF Transfer Printing:

-

Traditional Screen Printing:

Color Reproduction and Detail

When it comes to color and detail, DTF excels:

| Feature |

DTF Transfer Printing |

Traditional Screen Printing |

| Color Range |

Unlimited full-color |

Limited by number of screens |

| Detail |

High-definition, intricate |

Good, but less detailed |

| Best For |

Complex designs |

Simple designs |

Durability and Longevity

Both methods offer durability, but there are some differences:

-

DTF Transfers can last long with proper care, making them suitable for custom iron on transfers for shirts.

-

Screen Printing is known for its longevity, especially when applied directly to fabric.

-

Both methods can withstand multiple washes, but screen printing may have a slight edge in durability.

In summary, choosing between DTF and screen printing depends on your specific needs, such as design complexity and desired durability. DTF is ideal for custom apparel printing with vibrant colors, while screen printing is great for bulk orders of simpler designs.

Versatility and Application of DTF Transfer Printing

Suitable Fabrics and Materials

DTF transfer printing is incredibly versatile, allowing for application on a variety of fabrics. Here are some suitable materials:

-

Cotton: Ideal for most designs due to its smooth texture.

-

Polyester: Works well but may need different heat settings.

-

Blends: Cotton-polyester blends are also effective, but testing is recommended.

Customization and Creativity

One of the standout features of DTF printing is its ability to create custom iron-on DTF transfers. This method allows for:

-

Intricate Designs: You can print detailed images without losing quality.

-

Full-Color Options: DTF excels at producing vibrant, full-color designs.

-

Personalization: Perfect for unique items like custom apparel or gifts.

Ease of Use and Accessibility

DTF transfer printing is user-friendly, making it accessible for both beginners and professionals. Here’s why:

-

Quick Setup: Minimal preparation is needed compared to traditional methods.

-

No Special Skills Required: Even those new to printing can achieve great results.

-

Fast Turnaround: Ideal for small batch orders or urgent projects.

DTF transfers are a great choice for anyone looking to create high-quality, personalized items. They offer a unique blend of durability and vibrancy, making them suitable for various applications, from clothing to home decor.

In summary, DTF transfer printing stands out for its versatility, allowing users to explore their creativity while ensuring high-quality results across different materials and designs.

Cost-Effectiveness of DTF Transfer Printing

Initial Setup and Equipment Costs

Setting up for DTF transfer printing is generally more affordable than traditional screen printing. Here are some key points:

-

Lower initial costs: DTF printing requires less expensive equipment compared to screen printing, which needs multiple screens and inks.

-

Minimal setup fees: You can start printing without the high costs associated with screen printing setups.

-

Versatile equipment: A single DTF printer can handle various designs, making it suitable for small businesses.

Cost Per Print Comparison

When comparing costs per print, DTF transfers can be more economical for smaller batches:

| Printing Method |

Cost Per Print (Approx.) |

Best For |

| DTF Transfer Printing |

$1.00 - $3.00 |

Small batches, custom designs |

| Screen Printing |

$2.00 - $5.00 |

Large quantities, simple designs |

Economic Benefits for Small Batch Orders

DTF printing shines when it comes to small orders:

-

No minimum order requirement: You can print just one or a few items without extra costs.

-

Quick turnaround: DTF allows for faster production, which is great for urgent needs.

-

Creative freedom: You can experiment with designs without worrying about high costs.

DTF printing is a cost-effective solution for those looking to create unique designs without breaking the bank. It allows for full-color designs without the limitations of traditional methods, making it ideal for creative projects.

Environmental Impact of DTF and Screen Printing

Sustainability of DTF Printing

DTF printing is considered a more eco-friendly option compared to traditional screen printing. Here are some key points:

-

Water-Based Inks: DTF uses water-based inks that are non-toxic and biodegradable, reducing harmful chemical usage.

-

Less Waste: Unlike screen printing, DTF does not require the creation of screens, which means less waste is generated.

-

Lower Energy Consumption: DTF printing generally consumes less energy, contributing to a smaller carbon footprint.

Environmental Concerns with Screen Printing

Screen printing has several environmental drawbacks:

-

Chemical Use: The process involves harmful chemicals and solvents, which can be damaging to both health and the environment.

-

Screen Waste: Each design requires a new screen, leading to significant waste when designs change.

-

Water Usage: Screen printing often requires large amounts of water for cleaning screens and equipment.

Choosing the Eco-Friendly Option

When deciding between DTF and screen printing, consider the following:

-

Material Impact: DTF printing is better for the environment due to its use of sustainable materials.

-

Waste Reduction: DTF minimizes waste by eliminating the need for screens.

-

Health Safety: Water-based inks in DTF are safer for both users and the environment.

In summary, DTF printing represents a step towards a greener future in the printing industry, making it a sustainable choice for businesses and consumers alike.

Choosing the Right Printing Method for Your Needs

When deciding between DTF transfer printing and traditional screen printing, it's essential to consider your specific needs and goals. Understanding the differences can help you make the best choice for your project.

Factors to Consider

-

Design Complexity: DTF printing excels at reproducing intricate designs with vibrant colors, making it ideal for detailed artwork.

-

Fabric Compatibility: DTF transfers can be applied to a wide range of fabrics, including dark and textured materials, while screen printing works best on lighter fabrics.

-

Production Volume: If you need a large number of prints, screen printing may be more cost-effective in bulk, but DTF is great for smaller batches.

Pros and Cons of Each Method

| Feature |

DTF Transfer Printing |

Traditional Screen Printing |

| Setup Time |

Quick setup for small runs |

Longer setup for each design |

| Color Range |

Wide color range with fine details |

Limited by the number of screens |

| Durability |

Highly durable, withstands many washes |

Very durable, but can fade over time |

Making the Final Decision

Ultimately, the choice between DTF transfer printing and traditional screen printing depends on your specific needs. If you prioritize vibrant colors and detailed designs, DTF might be the way to go. However, if you're looking for a cost-effective solution for large orders, screen printing could be more suitable.

Choosing the right printing method can significantly impact the quality and success of your project. Take the time to evaluate your options carefully!

Conclusion

In summary, DTF transfer printing and traditional screen printing each have their own strengths. DTF is great for colorful and detailed designs, making it perfect for small orders or unique items. It’s easy to use and saves time, which is a big plus for busy creators. On the other hand, screen printing is a tried-and-true method that works well for larger batches and simpler designs. It’s known for its durability and vibrant colors. Choosing between them depends on what you need for your project. Whether you go with DTF or screen printing, both methods can help you create amazing custom apparel.

Frequently Asked Questions

What is DTF Transfer Printing?

DTF Transfer Printing, or Direct-to-Film Transfer Printing, is a modern technique where designs are printed on a special film and then transferred to fabric using heat and pressure.

How does DTF Transfer Printing work?

In DTF printing, your design is first printed onto a special film. This film is then placed on the fabric, and heat is applied to transfer the design.

What materials can I use DTF Transfers on?

DTF Transfers can be used on many types of fabrics, including cotton, polyester, and blends, as well as some other surfaces like leather.

Is DTF Transfer Printing cost-effective?

Yes, DTF Transfer Printing is often more affordable, especially for small batches, as it doesn't require expensive setup fees like traditional methods.

How durable are DTF Transfers?

DTF Transfers are known for their durability and can withstand many washes if applied correctly, maintaining their vibrant colors.

What are the advantages of using DTF over traditional screen printing?

DTF offers more design flexibility, allows for full-color prints without extra costs, and is easier for small orders compared to traditional screen printing.

0 comments