In the world of custom printing, Direct-to-Film (DTF) transfers are gaining popularity due to their impressive durability and vibrant designs. This article explores how long DTF transfers last, especially after multiple washes, and what factors contribute to their longevity. Understanding these aspects can help consumers make informed choices about their custom apparel and ensure they enjoy their designs for a long time.

Key Takeaways

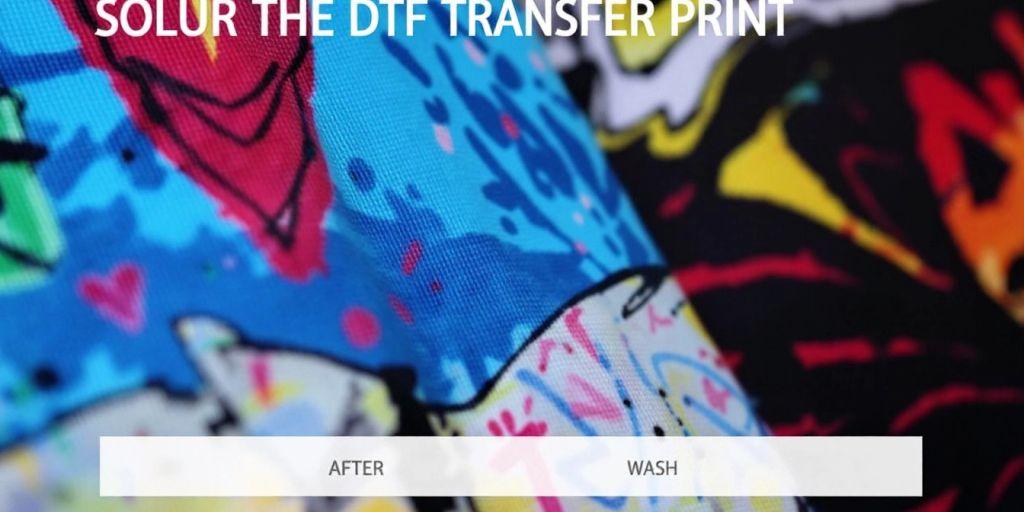

- DTF transfers can last over 45 washes without fading or cracking when cared for properly.

- Using high-quality materials and inks enhances the durability of DTF prints.

- Different fabrics may affect the longevity of DTF transfers, with synthetic options generally performing better.

- Following proper washing and drying instructions is crucial for maintaining print quality.

- DTF transfers are versatile and can be applied to various materials, not just fabrics.

Understanding DTF Transfer Prints

What is DTF Transfer Printing?

DTF Transfer printing, or Direct-to-Film printing, is a modern method for creating custom designs on various materials. This technique allows you to print vibrant, full-color images directly onto a special film, which can then be transferred onto fabrics like cotton and polyester. One of the biggest advantages of DTF printing is that it can produce designs with unlimited color possibilities, making it a favorite among designers.

How Does DTF Transfer Printing Work?

The DTF printing process involves several key steps:

-

Design Creation: Start by designing your artwork using compatible file formats like JPG, PNG, or TIFF.

-

Printing on Film: The design is printed onto a special film using a DTF printer.

-

Applying Adhesive Powder: After printing, a special powder is applied to the wet ink to help it stick to the fabric.

-

Heat Transfer: Finally, the film is placed on the fabric and heat is applied using a heat press to transfer the design.

Benefits of DTF Transfer Printing

-

High-Quality Prints: DTF printing produces detailed and vibrant designs that stand out.

-

Versatility: It works on various fabrics, including dark and light materials.

-

Cost-Effective: Ideal for small batches, DTF printing eliminates the need for expensive setup fees.

DTF Transfer printing is a game-changer for custom apparel, allowing for creativity without limits.

In summary, DTF Transfer printing is a powerful tool for anyone looking to create stunning, full-color designs on fabric. With its ease of use and high-quality results, it’s no wonder that this method is gaining popularity in the world of custom apparel printing.

Factors Affecting the Durability of DTF Transfers

Quality of Materials Used

The quality of materials plays a crucial role in how long DTF transfers last. Using high-quality transfer paper and inks can significantly enhance durability. Here are some key points:

-

High-quality inks ensure better adhesion and color retention.

-

Transfer films should be chosen based on the fabric type for optimal results.

-

Avoid low-grade materials that can lead to peeling or fading.

Application Process

The way DTF transfers are applied can also impact their lifespan. Proper application techniques are essential:

-

Pre-press the fabric to remove moisture.

-

Use the correct heat settings for the specific material.

-

Apply even pressure during the transfer process.

Fabric Type

Different fabrics react differently to DTF transfers. Here’s a quick comparison:

| Fabric Type |

Durability |

Notes |

| Cotton |

High |

Excellent adhesion and comfort |

| Polyester |

Moderate |

May require different heat settings |

| Blends |

Variable |

Test for best results |

Environmental Exposure

Environmental factors can also affect the durability of DTF transfers. Consider the following:

-

Sunlight exposure can fade colors over time.

-

Harsh weather conditions may lead to quicker wear.

-

Frequent washing can impact the transfer's integrity if not done properly.

Understanding these factors can help you maintain the quality of your DTF transfers, ensuring they last longer and look great even after multiple washes. Proper care and quality materials are key!

Proper Care for DTF Transfer Prints

Washing Instructions

To keep your DTF transfers looking fresh, always wash your garments inside out. This protects the design from rubbing against other clothes. Here are some key tips:

- Use a gentle cycle with cold water.

- Avoid bleach, as it can fade the image.

- Most fabrics can handle up to 20 washes without significant wear.

Drying Tips

For drying, it's best to air dry your fabric. If you must use a dryer, choose a low heat setting. High heat can cause the transfer to peel or wrinkle.

Ironing and Storage Guidelines

To ensure your design lasts, avoid ironing directly on the transfer. If you need to iron, place a cloth over the design. This will help maintain the vibrant colors and prevent damage. Here are some storage tips:

- Store items in a cool, dry place to prevent damage.

- Avoid folding them in a way that puts pressure on the transfer.

- If you notice any peeling or cracking, address it immediately to prevent further damage.

Taking good care of your custom DTF transfers will keep them looking new and vibrant for many washes. No peeling, no wrinkles—just beautiful, lasting designs.

Comparing DTF Transfers with Other Printing Methods

When it comes to printing on fabric, DTF (Direct-to-Film) printing stands out among various methods. Here’s how it compares to some popular alternatives:

DTF vs. Screen Printing

-

Setup Costs: DTF requires a lower initial investment compared to screen printing, which often needs multiple screens for different colors.

-

Design Complexity: DTF excels in producing intricate designs and vibrant colors, making it ideal for small batches. In contrast, screen printing is better suited for larger orders.

-

Durability: Both methods are durable, but DTF prints may feel slightly plasticized.

DTF vs. Direct-to-Garment (DTG)

| Feature |

DTF Printing |

DTG Printing |

| Investment |

Lower initial cost |

Higher initial cost |

| Production Speed |

Slower due to multiple steps |

Faster, prints directly on fabric |

| Color Quality |

Excellent for full-color designs |

Great, but may vary by fabric |

| Fabric Compatibility |

Works on various fabrics |

Best on cotton |

DTF vs. Heat Transfer Vinyl (HTV)

-

Process Complexity: DTF is simpler as it prints the white layer simultaneously with the color layer, while HTV requires separate steps.

-

Cost Efficiency: DTF is generally more cost-effective, with lower consumable costs compared to HTV systems.

-

Print Feel: Both methods have a similar finish, but DTF inks provide greater elasticity and wear resistance.

In summary, DTF printing offers a versatile and cost-effective solution for creating vibrant, full-color designs on various fabrics, making it a strong contender against traditional methods like screen printing and DTG.

Real-World Performance of DTF Transfers

Case Studies on Durability

Numerous studies have shown that DTF transfers can endure over 45 washes without fading or cracking. This durability makes them a popular choice for custom apparel. Here are some key findings:

| Study Source |

Washes Endured |

Fading Observed |

Cracking Observed |

| Sam's DTF Transfers |

45+ |

None |

None |

| DTF Rush Orders |

50-100 |

Minimal |

None |

Customer Testimonials

Many customers have shared their experiences with DTF transfers:

- "I was amazed at how vibrant the colors stayed after multiple washes!"

- "These transfers are tough! I’ve washed my shirt over 30 times, and it still looks new."

- "I love how easy it is to apply and how well it holds up!"

Expert Opinions

Experts in the field agree that DTF transfers are a game-changer. They highlight:

-

High-quality inks that penetrate deeply into the fabric.

-

Strong adhesion that resists wear and tear.

-

Versatility across various fabric types, including cotton and leather.

DTF transfers are not just about looks; they are built to last, making them a smart choice for anyone looking to create custom designs that endure.

Overall, the real-world performance of DTF transfers showcases their durability and effectiveness, making them a top choice for custom printing needs.

Enhancing the Lifespan of DTF Transfers

Using High-Quality Inks and Films

To ensure your DTF transfers last longer, start with high-quality materials. Using premium inks and films can significantly improve durability. Here are some benefits:

- Better adhesion to fabrics

- Resistance to fading and cracking

- Enhanced color vibrancy

Following Manufacturer's Instructions

Always follow the manufacturer's guidelines for application and care. This includes:

- Pre-pressing the fabric to remove moisture.

- Setting the correct temperature and pressure during application.

- Allowing the transfer to cool before peeling.

Regular Maintenance and Inspections

Regularly check your DTF transfers for any signs of wear. Here are some maintenance tips:

- Wash garments inside out to protect the design.

- Use cold water and a gentle cycle to avoid damage.

- Store items in a cool, dry place to prevent deterioration.

By taking these steps, you can ensure that your DTF transfers remain vibrant and durable for a long time. Proper care is key to longevity!

Common Issues and Troubleshooting

Dealing with Peeling Transfers

If your DTF transfer starts to peel, it might be due to incorrect heat or pressure settings. Here’s how to fix it:

-

Check the heat press temperature: Make sure it’s set correctly.

-

Follow the instructions: Always adhere to the guidelines provided with your transfer paper.

-

Consider using a heat press: This can help achieve more consistent results.

Fixing Faded Designs

Faded designs can be frustrating, especially after washing. To prevent this:

-

Wait 24 hours before washing a freshly pressed garment.

-

Turn the garment inside out to protect the design.

-

Use a gentle wash cycle with cold water.

If you notice fading, it might be due to the quality of the inks or transfer paper used. For better results, use high-quality materials.

Preventing Fabric Damage

To keep your fabric safe while using DTF transfers:

-

Avoid direct ironing on the transfer: If you need to iron, place a cloth over the design.

-

Store items properly: Keep them in a cool, dry place to avoid damage.

-

Check for wear regularly: Address any signs of peeling or cracking immediately to prevent further issues.

Remember, taking care of your DTF transfers will keep them looking fresh and vibrant for a long time. Proper maintenance is key!

Final Thoughts on DTF Transfer Durability

In conclusion, DTF transfers are a fantastic choice for anyone looking for long-lasting designs on their clothing. With proper care, these prints can survive over 45 washes without fading or cracking. This means your favorite shirts and other items will keep looking great for a long time. The special inks used in DTF printing bond well with various fabrics, ensuring that the colors stay bright and the designs remain intact. So, if you want vibrant and durable prints, DTF transfers are definitely worth considering!

Frequently Asked Questions

What are DTF transfers?

DTF transfers, or Direct-to-Film transfers, are a way to print designs directly onto a special film. This film is then applied to different fabrics using heat and pressure.

How long do DTF transfers last?

With proper care, DTF transfers can last through 50 to 100 washes without fading or cracking.

Can I use DTF transfers on any fabric?

Yes, DTF transfers work well on various fabrics, including cotton, polyester, and leather.

What should I do to care for my DTF printed items?

To keep DTF prints looking great, wash them inside out in cold water and avoid bleach. Air drying is best.

Are DTF transfers better than other printing methods?

DTF transfers are often more durable than methods like screen printing and heat transfer vinyl, making them a great choice for long-lasting designs.

How can I prevent fading of my DTF prints?

Always wash your garments inside out and use gentle cycles with cold water to help prevent fading.

0 comments