Love this DTF! Great colors! I love most of all what it says. I will be a returning customer

Quality is the best. Customer service is the best. Very happy

Direct to Film (DTF) printing is revolutionizing the custom apparel industry. This innovative technique allows for high-quality, durable designs on a wide range of fabrics. Whether you're a business looking for branded merchandise, a designer wanting to bring your creations to life, or someone looking to make a personal statement with custom apparel, understanding DTF transfers is key. Here's your ultimate guide to Custom DTF Transfers to navigating the world of custom apparel business, from submitting your designs to choosing the right apparel.

Direct to Film printing, a relatively new technology in the textile industry, has quickly become a favorite for its versatility and quality. Unlike traditional screen printing, which requires extensive setup for each design, DTF printing can easily accommodate small batches or individual pieces, making it perfect for custom orders.

To ensure the best results for your DTF transfers, start with high-resolution designs. Most DTF printers require designs in PNG or TIFF formats with a transparent background. When submitting your design, consider the size of the apparel and the placement of the design. For gang sheets, organizing multiple designs efficiently on the sheet can save you money and materials.

When preparing your design for DTF transfers, keep the following guidelines in mind:

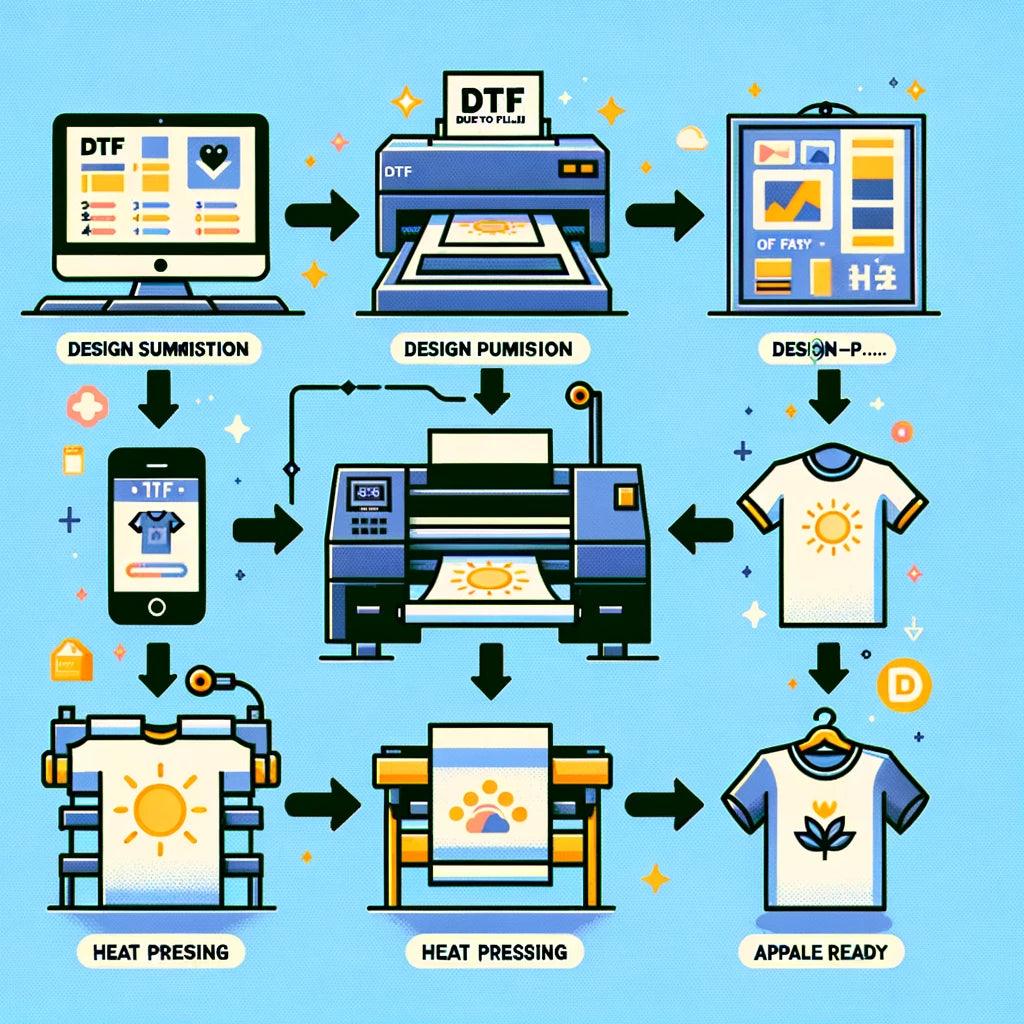

The DTF printing process involves printing a design onto a special film, coating it with adhesive powder, and then heat pressing it onto the fabric. One of the unique aspects of DTF printing is the hot-peeling technique, where the film is removed while still hot, resulting in vibrant and crisp transfers that are highly durable.

The DTF printing process typically involves these steps:

DTF transfers work on a wide range of fabrics, but for the best results, choose apparel made of cotton, polyester, or a blend of both. The color and texture of the fabric can affect the appearance of your design, so consider these elements when planning your custom apparel.

For businesses or events, bulk orders can be cost-effective. Our on-demand printing service allows you to submit your designs, which we then print and transfer onto the apparel of your choice. This service is ideal for companies looking to offer custom merchandise without the need for inventory.

Benefits of our on-demand printing service include:

To ensure the longevity of your DTF printed apparel, wash garments inside out in cold water and tumble dry on low heat. Avoid ironing directly on the design. Proper care will keep your custom apparel looking great for years to come.

Custom DTF transfers offer unparalleled flexibility and quality for personalized apparel. By following the guidelines for design submission, choosing the right fabric, and caring for your custom items properly, you can enjoy vibrant, durable designs on your favorite pieces. Ready to bring your designs to life? Contact us today to get started on your custom DTF printing project.

No comments

0 comments