Ironing DTF Transfers: A Guide to Safe and Effective Application

Ironing DTF Transfers: A Guide to Safe and Effective Application

While DTF transfers are known for their durability and ease of use, achieving flawless application sometimes requires a gentle touch. Here's what you need to know about ironing DTF transfers:

Why Ironing with Caution is Crucial:

DTF transfers feature vibrant inks that can be heat-sensitive. Direct ironing at high temperatures can damage the design, causing scorching, melting, or unwanted color bleeding.

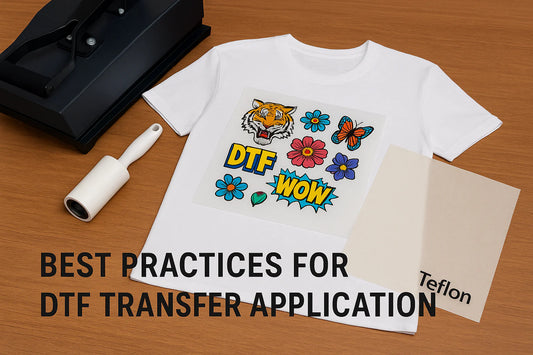

Safe Ironing Techniques:

If ironing becomes necessary, prioritize protecting the transfer:

- Protective Barrier: Use a protective layer between the iron and the DTF transfer. Parchment paper or a thin, heat-resistant fabric like teflon sheet are ideal choices.

- Low Heat Setting: Select the lowest heat setting possible on your iron. Ideally, use a setting specifically designated for synthetics or delicates.

- Quick and Gentle Touches: Apply minimal pressure and avoid lingering the iron on the transfer for extended periods. Use short, firm presses with a lifting motion.

Alternative Application Methods:

For optimal results and avoid any risk of damage, consider these alternatives to ironing:

- Heat Press: A heat press applies consistent heat and pressure, ensuring a professional-looking application with minimal effort. This is the recommended method for frequent use or large quantities.

In addition to the written guide, this YouTube video (https://m.youtube.com/watch?v=uEt20T-bWnc) also offers a visual demonstration of the heat press application process:

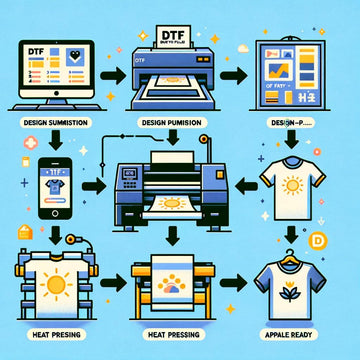

Heat Press Application: A Step-by-Step Guide

Here's a breakdown of the heat press application process, incorporating the key points you provided:

1. Placement

- Surface Preparation: Start by ensuring your work surface is clean, smooth, and free of wrinkles.

- Alignment: Be gentle when handling the transfer film. Avoid excessive bending to prevent creases.

- Transfer Handling: Handle the transfer film with care to avoid creases or smudges that could affect the final print quality.

2. Pressing

- Temperature and Time Settings: Adjust your heat press to 310°F (about 154°C). Set the pressure to medium or high. Press for approximately 10 to 11 seconds for optimal results.

- Pressure: Ensure even pressure distribution. Adjust the pressure based on the material thickness.

- Safety Tips: Always wear heat-resistant gloves and maintain a safe distance from the heat press plate to avoid burns.

3. Peeling

- Peeling: After waiting for 5 seconds, carefully peel the film at a steady angle and speed, starting from a corner.

- Troubleshooting: If any part of the design hasn't transferred, repress the area for a few seconds and attempt peeling again.

Remember: When in doubt, a little caution goes a long way! For best results, always refer to the specific application instructions provided by your DTF transfer supplier.

No comments

0 comments