Understanding DTF Transfers: A Complete Guide

In the world of custom printing, DTF transfers are a game-changer. They offer a versatile and cost-effective solution for creating high-quality prints on various materials.

But what exactly are DTF transfers? And why are they becoming increasingly popular in the printing industry?

This guide will provide a comprehensive understanding of DTF transfers. We'll explore their benefits, how they work, and why they're an excellent choice for your printing needs.

Whether you're a small business owner, a hobbyist, or a professional in the apparel industry, this guide will help you navigate the world of DTF transfers ready to press.

What Are DTF Transfers?

DTF, or Direct to Film, transfers is a modern printing technology. They allow you to print designs onto a special film, which is then transferred onto fabric.

Unlike traditional methods, DTF transfers can be used on various materials. You aren't restricted to cotton; polyester, nylon, and more can be used.

This process involves printing your design on a film using a special printer. A powder adhesive is applied to the printed film, ensuring a strong bond to the fabric.

What sets DTF apart is its ability to capture fine details. Colors are vibrant and sharp, making your designs stand out.

Moreover, DTF transfers offer durability. They withstand multiple washes without fading, making them ideal for items exposed to frequent wear.

The Advantages of DTF Transfers

DTF transfers offer numerous benefits, making them a preferred choice for many. They provide flexibility in material selection.

The vibrant colors and detailed prints are a major plus. Your designs will have depth and clarity, appealing to customers.

Here are some key advantages of using DTF transfers:

- Suitable for all fabric types, not just cotton.

- High-quality results with vivid colors.

- Strong and durable, resisting washing wear.

Another notable advantage is the quick application. The ready-to-press nature saves valuable time in production.

How DTF Transfers Work: The Process

DTF transfers begin with digital design creation. This step involves using software to prepare your graphics or artwork.

Once the design is ready, it's printed onto a special film. This film acts as the base for the transfer process.

After printing, a powder adhesive is applied to the film. The adhesive ensures the design bonds well to the fabric.

The film is then cured, setting the adhesive into place. This step is crucial for the durability of the transfer.

Once cured, the DTF transfer sheet is ready to use. With a heat press, the design transfers from the film to the garment.

Finally, the process results in a vibrant and long-lasting print. The ease and efficiency make DTF transfers appealing.

Types of DTF Transfers Available

DTF transfers offer a range of options for creative projects. These options cater to different needs in the printing industry.

Some of the popular types of DTF transfers include:

- Custom Designs: Tailored specifically to your artwork or logo.

- Pre-Made Transfers: Ready-made designs for convenience and quick application.

- Specialty Transfers: Include glitter or metallic finishes for unique effects.

Each type serves distinct purposes, providing flexibility for various applications. This versatility makes DTF transfers suitable for diverse printing tasks. Whether you need a quick solution or a unique creation, there is a DTF option for you.

Customization and Pre-Made Options

DTF transfers shine with their customization potential. You can create unique, personalized designs for any project. These designs reflect your brand's identity or personal touch effortlessly.

Pre-made options offer a convenient alternative. They're perfect for those needing quick solutions without compromising on style. Many designs are readily available, spanning a wide range of themes and styles.

Customization extends beyond just design. You can select different finishes, colors, and sizes to fit your needs. This flexibility makes DTF transfers a versatile choice for anyone seeking tailored outputs.

Combining both options allows ultimate creative freedom. Enjoy the perfect balance of personalization and convenience.

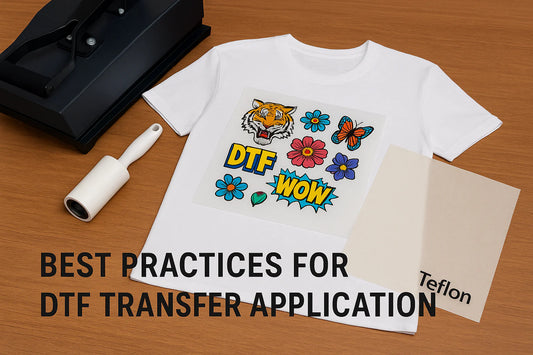

Applying DTF Transfers: A Step-by-Step Guide

Getting started with DTF transfers is easy:

- Ensure your fabric is clean and dry. This prepares the surface for optimal adhesion of the transfer.

- Set up your heat press to the correct temperature. Each transfer type may require different settings, so check the instructions. Proper temperature ensures vibrant color and strong adherence.

- Position your DTF transfer on the garment. Make sure the design is placed as desired. It's important to align accurately to avoid mistakes.

- Cover the transfer with a protective sheet. This prevents direct heat damage during pressing.

- Press the transfer using firm, even pressure. Hold the press closed according to the recommended time. Timing is critical to ensure the design transfers properly.

- Let the garment cool before removing the film. This helps the transfer set and minimizes peeling.

Now, your custom piece is ready for wear!

Cost-Effectiveness and Quality of DTF Transfers

DTF transfers offer an economical solution for custom printing needs. Their affordability makes them a favorite among small businesses. You can create stunning designs without a huge investment.

The quality of DTF transfers is impressive. Prints are sharp and vibrant, ensuring your designs stand out. Their durability ensures they last through washes.

With DTF transfers, you get value for your money. High-quality prints at a lower cost make them ideal for bulk orders. This efficiency is beneficial for businesses of all sizes.

DTF transfers also help reduce waste. You only print what you need, making them an eco-friendly option. This approach supports sustainable business practices.

Troubleshooting Common DTF Transfer Issues

Experiencing issues with DTF transfers can be frustrating. Here are some common problems and solutions:

- Poor adhesion: Check the heat press temperature for accuracy.

- Print cracking or peeling: Ensure you're using the proper pressure settings.

- Fading colors: Always follow wash care instructions to maintain vibrancy.

- Misaligned designs: Check placement before pressing to ensure a professional finish.

Conclusion: Why Choose DTF Transfers for Your Printing Needs

DTF transfers offer a versatile solution for custom apparel. Their ease of use and vibrant results make them stand out.

Whether you're a small business or a hobbyist, DTF transfers provide high-quality, ready-to-press options. They ensure creativity and efficiency in every project.

0 comments