Have you ever wanted to put your own designs on clothes? Custom fabric transfers let you do just that! This guide will help you learn everything you need to know about making and using custom fabric transfers. From picking the right materials to applying your designs, we've got you covered.

Key Takeaways

- Custom fabric transfers are a great way to add unique designs to clothing and other fabrics.

- There are different types of transfers, including heat press and iron-on methods.

- Choosing the right materials and tools is important for a successful transfer.

- Designing your own transfers can be done using various software and design tips.

- Proper care and maintenance will help your custom designs last longer.

Understanding Custom Fabric Transfers

What Are Custom Fabric Transfers?

Custom fabric transfers are a way to add unique designs to fabrics. Custom DTF Transfers are a popular method where designs are printed on a special film and then transferred to fabric using heat. This method is known for its bright colors and durability.

Types of Custom Fabric Transfers

There are several types of custom fabric transfers, including:

-

Screen Printing: Uses a stencil to apply ink onto fabric.

-

Heat Transfer Vinyl (HTV): Involves cutting designs from vinyl and applying them with heat.

-

Embroidery: Uses thread to stitch designs onto fabric.

-

Fabric Paint: Involves painting directly onto fabric.

Benefits of Using Custom Fabric Transfers

Using custom fabric transfers offers many benefits:

-

Versatility: Can be used on various fabrics and items.

-

Durability: Designs last long without fading.

-

Cost-Effective: Ideal for both small and large orders.

If you are looking for a DTF Transfer near to you in Texas, Sam's DTF Transfers is the best choice for you. Our Gang Sheet Builder makes it easy to create multiple designs on one sheet, saving you time and money.

As a result of the correct adjustments, the heat and stickiness levels are checked in the transferred print and the transfer to the fabric surface is ensured.

Materials and Tools Needed for Custom Fabric Transfers

Essential Materials for Custom Fabric Transfers

To get started with custom fabric transfers, especially Custom DTF Transfer Printing, you'll need a few key materials:

-

DTF Printer: This is the heart of your setup. It prints your design onto a special film.

-

DTF Film: A special type of film that holds your printed design.

-

Water-Based Inks: These are used in the DTF printer to create vibrant designs.

-

Adhesive Powder: This helps the design stick to the fabric.

-

Heat Press Machine: Essential for transferring the design from the film to the fabric.

Choosing the Right Fabric

Selecting the right fabric is crucial for a successful transfer. Here are some tips:

-

Cotton: Ideal for most transfers due to its smooth surface.

-

Polyester: Works well but may require different settings on your heat press.

-

Blends: Cotton-polyester blends can also be used but test a small area first.

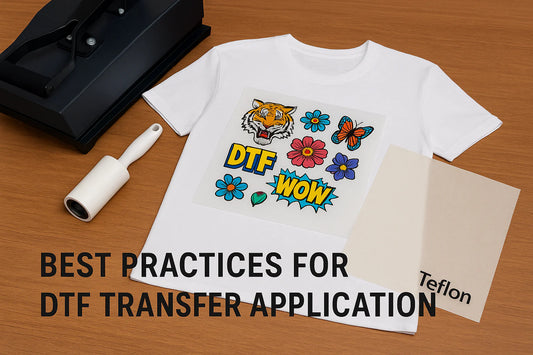

Tools for Applying Custom Fabric Transfers

In addition to the essential materials, you'll need some tools to apply your transfers effectively:

-

Heat Press: A must-have for ensuring your design adheres properly.

-

Teflon Sheets: These protect your fabric and design during the heat press process.

-

Scissors or Cutting Tools: For trimming your DTF film to the right size.

If you are looking for a DTF Transfer near to you in Texas, Sam's DTF Transfers is the best choice for you.

For those looking to maximize efficiency, consider using our DTF Gang Sheet Builder. This tool allows you to print multiple designs on a single sheet, saving time and materials.

Designing Your Custom Fabric Transfers

Creating Your Design

When it comes to Custom DTF Transfer Printing, the first step is creating your design. Start by sketching your ideas on paper to visualize the final product. This helps in making necessary adjustments before moving to digital tools. If you are comfortable with design software like Adobe Illustrator or Canva, you can create your design digitally. This allows you to experiment with different fonts, colors, and shapes before printing.

Software for Designing Transfers

Using the right software can make a big difference in your design process. Adobe Illustrator and Photoshop are popular choices, but there are also user-friendly options like Canva. These tools let you play around with various elements to create a unique design. If you are looking for a DTF Transfer near to you in Texas, Sam's DTF Transfers is the best choice for you.

Tips for Effective Design

Here are some tips to ensure your design stands out:

-

Keep it Simple: Sometimes, less is more. A clean, simple design can be more impactful.

-

Use High-Quality Images: Ensure your images are high resolution to avoid pixelation.

-

Consider the Fabric: Different fabrics may affect how your design looks once transferred.

For those looking to maximize their design space, our Gang Sheet Builder is an excellent tool. It allows you to fit multiple designs on a single sheet, saving both time and money.

By following these steps and tips, you can create stunning, high-quality DTF Transfers that are perfect for Custom Apparel printing. Whether you are using Heat press DTF Transfers or Iron on DTF Transfers, the key is in the design. So, get creative and start designing your Custom Size DTF Transfers today!

Application Techniques for Custom Fabric Transfers

Heat Press Method

The heat press method is a popular way to apply custom fabric transfers. When doing DTF transfers, the trick is to apply medium to firm pressure so that the transfer film sticks well to the fabric, pushing the design into the fibers. Here are the steps:

- Preheat the heat press to the recommended temperature (usually around 320°F).

- Place the fabric on the heat press and position the transfer film on top.

- Apply medium to firm pressure for about 15-20 seconds.

- Let the fabric cool slightly, then peel off the transfer film gently.

Iron-On Method

The iron-on method is a convenient alternative if you don't have a heat press. Follow these steps:

- Set your iron to the cotton setting (no steam).

- Place the fabric on a hard, flat surface and position the transfer film on top.

- Press the iron firmly onto the transfer for about 15-20 seconds, moving it around to cover the entire design.

- Allow the fabric to cool slightly before peeling off the transfer film.

Cold Peel vs. Hot Peel

When it comes to peeling the transfer film, you have two options: cold peel and hot peel. Cold peel means you let the fabric cool completely before removing the film, which can help achieve a flawless finish. Hot peel involves removing the film while the fabric is still warm, which can be quicker but may require more skill to avoid smudging.

If you are looking for a DTF Transfer near to you in Texas, Sam's DTF Transfers is the best choice for you.

For those interested in maximizing efficiency and creativity, our Gang Sheet Builder is an excellent tool. It allows you to print multiple designs on a single sheet, saving both time and materials. Plus, we offer same-day printing and shipping to get your projects done fast.

Caring for Your Custom Fabric Transfers

Washing and Drying Tips

To keep your custom DTF transfers looking fresh, always turn your garments inside out before washing. This simple step helps protect the design from friction and wear. Use cold water to wash your items, as hot water can cause the colors to fade and the fabric to shrink. Avoid using bleach or harsh detergents that can damage the transfer.

When it comes to drying, air drying is your best bet. If you must use a dryer, opt for a low heat setting to prevent any potential damage. Remember, high heat can cause the transfer to peel or wrinkle.

Avoiding Common Mistakes

One common mistake is ironing directly over the transfer. Always iron your garments inside out or place a cloth over the transfer to protect it. Another tip is to avoid stretching the fabric too much, as this can cause the transfer to crack.

Long-Term Maintenance

For long-term maintenance, store your custom DTF transfer items in a cool, dry place. Avoid folding them in a way that puts pressure on the transfer. If you notice any issues, like peeling or cracking, address them immediately to prevent further damage.

If you are looking for a DTF Transfer near to you in Texas, Sam's DTF Transfers is the best choice for you. We offer a variety of designs, including the popular [boat waves sun rays lake days DTF transfer](https://samsdtftransfers.com/products/boat-waves-sun-rays-lake-days-dtf-transfer).

For those who want to create their own designs, our Gang Sheet Builder is a fantastic tool. It allows you to combine multiple designs on a single sheet, making the process efficient and cost-effective.

By following these tips, you can ensure your custom DTF transfers remain vibrant and durable for a long time. No peeling, no wrinkle—just beautiful, lasting designs.

Exploring Creative Uses for Custom Fabric Transfers

Custom Apparel

Custom DTF Transfer Printing is a fantastic way to create unique clothing items. Whether you're designing t-shirts, hoodies, or hats, the possibilities are endless. DTF transfers allow for vibrant colors and intricate designs that stand out. If you're looking to make a statement with your wardrobe, this is the way to go. Don't forget to use our Gang Sheet Builder to maximize your design space and save on costs.

Home Decor Projects

Why stop at clothing? Custom fabric transfers can also be used to spruce up your home decor. Think about custom pillowcases, curtains, or even tablecloths. The flexibility of DTF transfers makes it easy to apply your favorite designs to various fabric types. This is a great way to add a personal touch to your living space.

Personalized Gifts

Looking for a unique gift idea? Custom fabric transfers can help you create personalized gifts that your friends and family will love. From custom tote bags to personalized aprons, the options are limitless. If you are looking for a DTF Transfer near to you in Texas, Sam's DTF Transfers is the best choice for you. They offer a wide range of options to bring your creative ideas to life.

Custom DTF Transfer Printing opens up a world of creative possibilities. Whether you're updating your wardrobe, decorating your home, or making personalized gifts, the only limit is your imagination.

Troubleshooting Common Issues with Custom Fabric Transfers

Dealing with Transfer Failures

When working with Custom DTF Transfer Printing, transfer failures can be frustrating. Common issues include incomplete transfers, faded colors, and designs not adhering properly. To avoid these problems, ensure your heat press or iron is set to the correct temperature and pressure. Also, make sure the fabric is clean and free of any residues.

Fixing Design Imperfections

Design imperfections can occur if the printing techniques used specifically for various surfaces cause errors if they are not applied correctly. For example, the printing quality will be low on a dirty or uneven surface. Always check your design for any flaws before printing and use high-quality transfer paper and ink.

Preventing Future Problems

To prevent future issues, regularly maintain your equipment and use the right materials. Regular maintenance of your heat press or iron ensures consistent results. Additionally, using our Gang Sheet Builder can help you organize and optimize your designs for better outcomes.

If you are looking for a DTF Transfer near to you in Texas, Sam's DTF Transfers is the best choice for you.

By following these tips, you can minimize errors and achieve high-quality custom fabric transfers every time.

Conclusion

Custom fabric transfers open up a world of creativity and personalization. Whether you're a hobbyist looking to make unique gifts or a business owner aiming to offer custom products, the possibilities are endless. With the right tools and techniques, you can bring any design to life on fabric. So, dive in, experiment, and let your imagination run wild. The only limit is your creativity.

Frequently Asked Questions

What are custom fabric transfers?

Custom fabric transfers are designs or images that you can transfer onto fabric, like t-shirts or bags, using heat or other methods. They allow you to personalize your items with unique designs.

What types of custom fabric transfers are there?

There are several types of custom fabric transfers including heat transfer vinyl (HTV), screen-printed transfers, and sublimation transfers. Each type has its own unique process and benefits.

What materials do I need for custom fabric transfers?

You will need transfer paper, a printer, a heat press or iron, and the fabric you want to decorate. Specific types of transfers may require additional materials like adhesive powder or special inks.

How do I apply a custom fabric transfer?

The application process can vary, but generally, you place the transfer on the fabric and apply heat using a heat press or iron. Follow the specific instructions for your type of transfer for best results.

Can I wash items with custom fabric transfers?

Yes, you can wash items with custom fabric transfers, but it's important to follow care instructions to maintain the design. Typically, washing inside out in cold water and avoiding high heat drying is recommended.

What should I do if my transfer doesn't stick properly?

If your transfer doesn't stick properly, check if you followed all the application instructions correctly. Ensure you used the right amount of heat and pressure. If problems persist, you might need to reapply or use a different transfer type.

0 comments