Excellent print made t-shirts for some teachers.

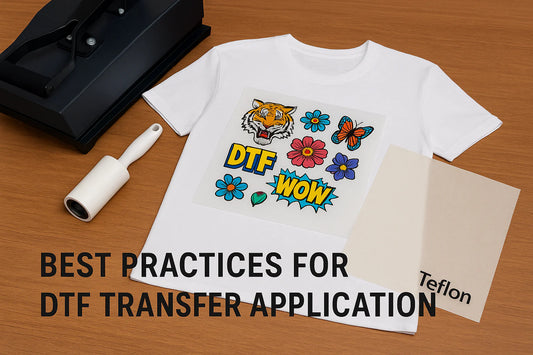

Step-by-Step Guide to DTF Transfers

Step-by-Step Guide to DTF Transfers

Direct to Film (DTF) transfers are a game-changer in the world of textile printing. They offer a unique blend of versatility, quality, and ease of use.

Whether you're a DIY enthusiast, a small business owner, or a professional printer, mastering DTF transfers can open up new opportunities. It can help you create stunning custom apparel, expand your services, or even start a new business.

This guide will walk you through the process of making DTF transfers. It will cover everything from the materials and equipment needed, to the design and printing process, and finally, the transfer to fabric.

We'll also share tips and tricks to ensure your DTF transfers come out perfect every time. Plus, we'll help you troubleshoot common issues and provide insights on how to make your DTF transfers last longer.

So, are you ready to dive into the world of DTF transfers? Let's get started.

Understanding DTF Transfers

DTF, or Direct to Film, printing is an innovative technique in garment customization. It allows for vivid and detailed designs to be transferred onto various fabrics.

Unlike traditional methods, DTF printing involves printing your design onto a special film. Then, using adhesive powder and heat, the design is transferred onto the fabric.

This method is highly versatile and suitable for different types of garments. It works well with cotton, polyester, and other fabric blends.

DTF transfers are gaining popularity because they are efficient and produce high-quality results. They are also more accessible for those looking to create transfers at home.

Advantages of DTF Transfers

One major advantage of DTF transfers is their versatility. They can be applied to nearly any fabric type, expanding your creative possibilities.

DTF transfers also deliver high-quality prints. The colors are vibrant and durable, which ensures that designs stand out and last longer.

Another benefit is the straightforward process involved. Whether you are a beginner or a seasoned professional, DTF printing offers an easy learning curve.

Materials and Equipment Needed

Creating DTF transfers requires specific materials and equipment. Having the right tools ensures quality and longevity of your transfers.

- DTF Printer: Essential for achieving vivid colors and precise details.

- DTF Transfer Films: Crucial for the printing and transfer process.

- Adhesive Powder: Helps the printed design stick securely to the fabric.

- Textile Inks: High-quality inks for vibrant prints.

- Heat Press Machine: For transferring the design onto fabric.

Make sure to have these items on hand. For detailed application steps, visit our DTF Heat Press Tutorial.

Choosing the Right DTF Printer

Selecting the right DTF printer is vital for successful transfers. Look for printers that offer high-resolution output.

Ease of use is another important factor. Beginners should consider models with user-friendly interfaces and features.

Research brands and models well. Read reviews and compare features to find the best option for your needs.

Designing Your DTF Transfer

The design phase is the foundation of a great DTF transfer. Start by conceptualizing your design to align with the project's purpose. Consider colors and elements that will appeal to your audience.

Use clear and bold imagery. Detailed designs often translate well to DTF transfers, showing every vibrant color.

Test your design on different backgrounds. This ensures it looks good, whether on light or dark materials.

For ready-made designs, explore our Ready-to-Press DTF Transfer Collection.

Maximizing Efficiency with Gang Sheets

Gang sheets allow you to group multiple designs on one sheet, saving time and resources.

Use a Gang Sheet Builder to strategically arrange designs and make the most of available space. This method reduces waste and enhances productivity.

Troubleshooting Common DTF Transfer Issues

Encountering issues with DTF transfers? Here are some common problems and solutions:

- Dull Colors: Check printer settings and ensure proper ink levels.

- Poor Adhesion: Verify heat press temperature and pressure settings.

- Misaligned Designs: Use guides or grids to ensure accurate placement.

Conclusion and Next Steps

By following this guide, you can confidently create quality DTF transfers. Every step, from design to print, matters.

Start exploring modern solutions like DTF Sheets and tools like the Gang Sheet Builder to streamline your workflow.

Q: How do I apply DTF transfers to garments?

A: To apply DTF transfers, use a heat press set to the appropriate temperature and pressure. Place the transfer on the garment, press it, and peel the film after cooling. For detailed instructions, visit our DTF Heat Press Tutorial.

Q: What sizes are recommended for different garments?

A: The recommended sizes for transfers depend on the garment type. Refer to our Size Guide for guidance on design placement and dimensions.

Q: Where can I get help with my DTF transfer process?

A: If you encounter issues or have questions about your DTF transfers, contact us via our Support Page for personalized assistance.