Beautifully Broken – Mental Health DTF Transfers Ready to Press

The delivery turn around time was fantastic!

The transfers are nice. they are really cute. They seem to work well so far. I put one on a cloth bag and another on a zipper vinyl bag.

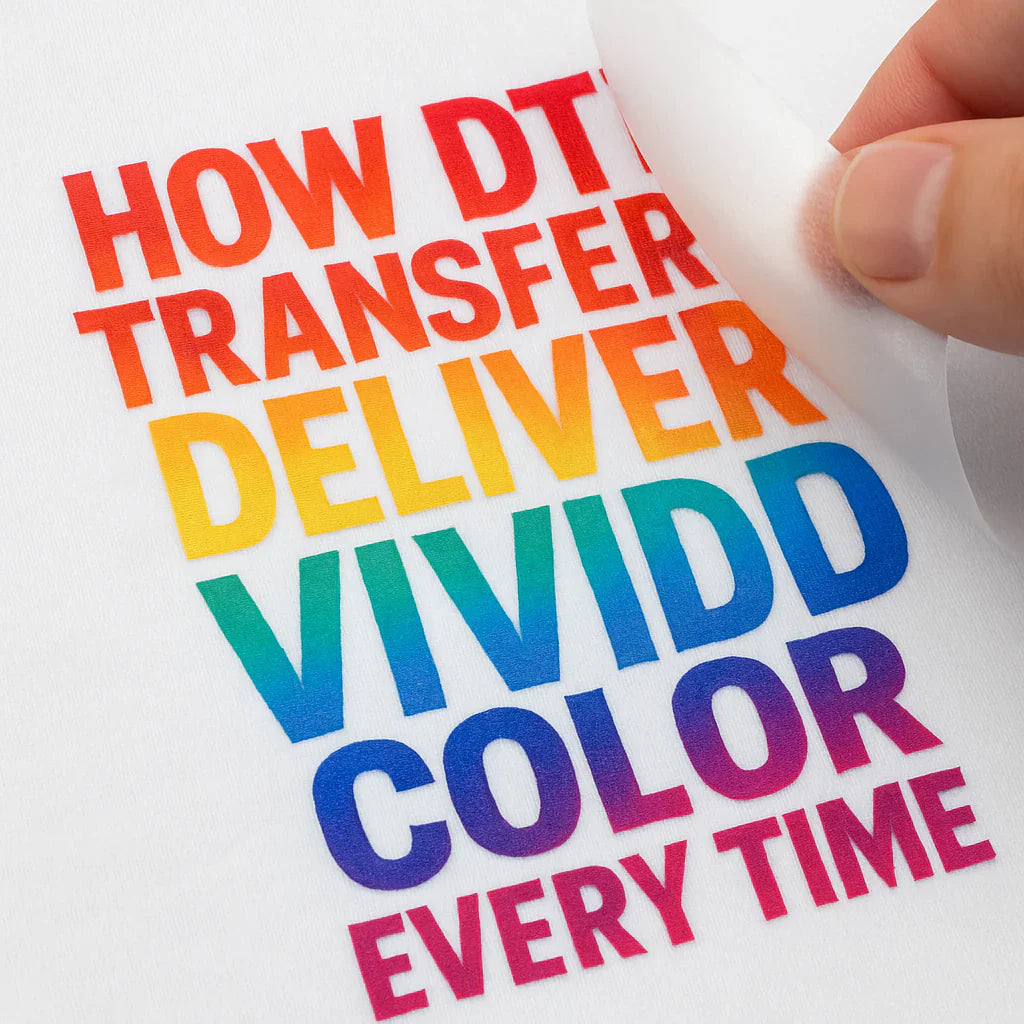

In the world of garment printing, DTF transfers are making waves. They are known for creating bright colors and high-quality prints. They are changing how designs are put on fabrics.

But what exactly are DTF transfers?

DTF means Direct to Film. It is a printing method that is becoming more popular because it is flexible and easy to use.

This article will delve into the meaning of DTF transfers, how they're made, and why they're renowned for their color vibrancy. If you own a print shop, work as a graphic designer, or want to learn about this technology, you will find helpful information here.

So, let's explore the colorful world of DTF transfers and discover how they consistently deliver vivid colors every time.

DTF transfers stand for Direct to Film transfers. This innovative method involves printing designs onto a special film. Once printed, the design is transferred onto fabric.

The process is straightforward and doesn't require complex pretreatment of garments. This makes it ideal for various applications, from T-shirts to bags.

Unlike other methods, DTF transfers offer exceptional detail retention. Fine lines and small text maintain clarity and sharpness.

Furthermore, DTF transfers are versatile. They work on both light and dark fabrics, accommodating many design preferences.

DTF transfers are renowned for their vibrant colors. The technology supports a wide color gamut, which ensures vivid prints.

Unlike other methods, DTF printing captures intricate hues and shades with precision. This results in eye-catching designs.

The use of special inks and film enhances color reproduction. This ensures that the final output is true to the original design.

Additionally, DTF transfers maintain their color brilliance even after multiple washes. This durability is a key advantage for many users.

The DTF printing process begins by printing a design onto a special film. This film is key to the transfer.

Next, a powder adhesive is applied to the printed film. This ensures the design sticks properly to the fabric.

The film is then cured through heat. This step solidifies the adhesive and prepares it for application.

Finally, the design is transferred to the garment with a heat press. This secures the vivid design onto the fabric.

Creating DTF transfers begins with selecting the right design software. This software helps ensure precision and quality in the digital design.

Once the design is finalized, it’s printed onto the special DTF film. This step requires a compatible printer capable of handling DTF inks.

After printing, apply the powder adhesive by sprinkling it onto the wet print. This powder adheres to the ink, preparing it for the next step.

The adhesive-covered film is then cured under heat to activate the adhesive. This step is crucial for achieving vibrant and durable colors.

Finally, the design is transferred onto the garment with a heat press. The result is a vivid and long-lasting print that adheres well and feels soft.

DTF transfers stand out due to their versatility. Unlike screen printing, DTF doesn't require color separation, simplifying the process.

Compared to DTG printing, DTF offers flexibility. You can use it on a wider variety of fabric types, including both light and dark garments.

DTF's eco-friendly process produces less waste than traditional methods. It enables on-demand production with less leftover inventory.

For the best results, use high-quality inks and films. They significantly impact the vividness of DTF color in your designs.

Proper maintenance of your DTF printer ensures consistent performance. Regular checks prevent unexpected issues that could affect print quality.

Precise heat press settings are vital. They enhance color vibrancy and ensure the transfer sticks firmly without flaws.

Storing DTF transfers properly can make a difference. Keep them in optimal conditions to preserve quality until you're ready to press.

DTF transfers shine with their vivid colors and versatility. They're ideal for various fabrics without pretreatment.

This printing method is also cost-effective for small runs. It combines quality with affordability, meeting diverse business needs.

Ultimately, DTF transfers offer a unique solution. Their ease of use and flexibility can enhance any printing project.

At Sam’s DTF Transfers, we offer high-quality, full-color DTF transfers that are vibrant, long-lasting, and ready to press. No matter what you are customizing, we offer same-day printing and shipping. This ensures your shirts, hoodies, bags, and other items arrive quickly and perfectly.

👉 Order Your Custom DTF Transfers Today

Looking to design your own?

Try our Free Gang Sheet Builder to create your layout before uploading:

👉 Use the Gang Sheet Builder

No comments

0 comments